ComBricks Drawings

The following series of drawings show how the basic ComBricks modules may be combined and used in PROFIBUS networks to provide 24/7 performance checking, logging and remote access to allow current real-time network status and recorded information to be seen – using only a browser program. Additionally, for hub applications, the backplane may be used for connection of additional new outgoing segments, with DP copper, PA copper, fibre optic or RS485-IS options available.

Simpler ComBricks sets, such as that shown immediately below, may be used for short term temporary deployment, for example in order to help with fault location or to confirm now solid and reliable network operation after commissioning, or for longer term ongoing network performance verification checks. Ongoing performance checking is particularly important where high plant availability and reliability must be ensured.

Remember that in all configurations, a single ComBricks PROFIBUS DP repeater channel is needed for connection of PROFIBUS DP signals from the network Master into that ComBricks set backplane!

It is worth mentioning that each of the ComBricks kits shown below are offered at slight purchase price discount from the cost of purchasing each of the included modules separately – and can easily then be extended by simply adding additional ComBricks modules to their right, should this be needed. To allow such kit extension, new ComBricks modules are each provided with single slot backplane plug in order to extend the initial set backplane to accommodate the new module, then providing both power and PROFIBUS network signals as necessary.

Further details for each of the different standard ComBricks kits and modules are shown via this link, with how to get started with your first ComBricks installation explained here.

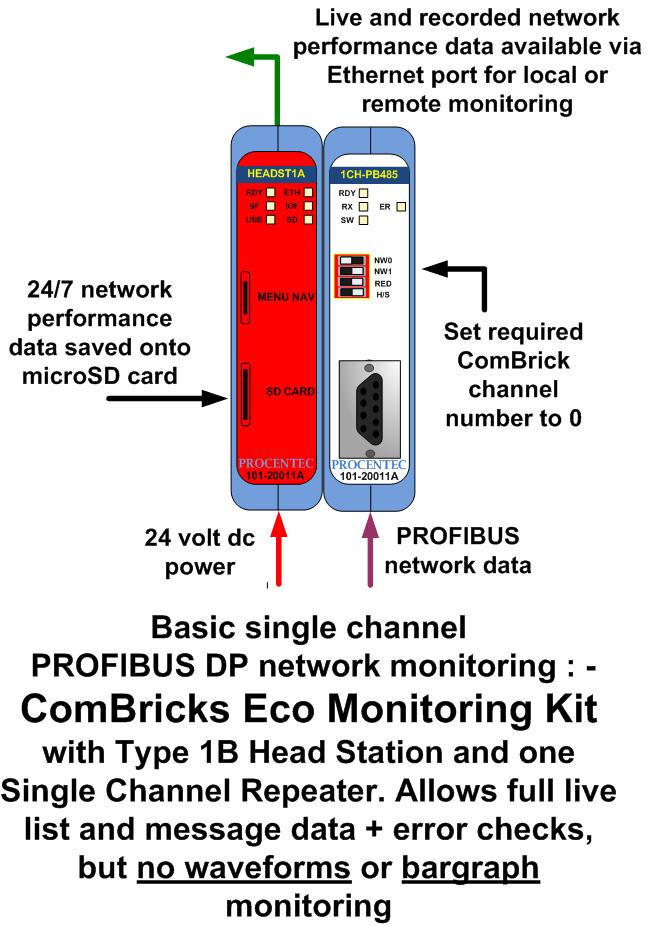

Basic ComBricks Monitoring Kit

When connected to a PROFIBUS DP network, near to the Master, this small ComBricks set can provide an extremely useful window into current network performance and be easily programmed, using a browser program running in a computer connected to the Head Station Ethernet port, to record any future message failure details. Links offered by the integrated web server allow display of connected ComBricks modules, with listing of active slaves connected to each repeater port. An additional Live List link gives ProfiTrace like graphic display of all slaves detected in the connected network, with top of screen drop list offering display of message error counts. Further links enable programming of error incident log messages onto the Head Station microSD card for later referral.

Although use of the above ComBricks Eco Monitoring Kit may seem restrictive, due to not being able to check network waveforms and signal levels, they are primarily installed to check and alert for very low level message error statistical weaknesses, such as Message Repeats or Illegal Messages, as these are usually the very first signs of network weakness and potential threatening failure!

Occasional message failures of this nature will not be seen by the control PLC, but ComBrick kit allows maintenance staff to track these, only needing to address in more detail should they start to occur more frequently, hence allowing for ‘preventive maintenance screening’ in good time, before any related plant failure might occur. In the event of more frequent message failures, ProfiTrace kit would be needed to look further into the location and causes of these weaknesses.

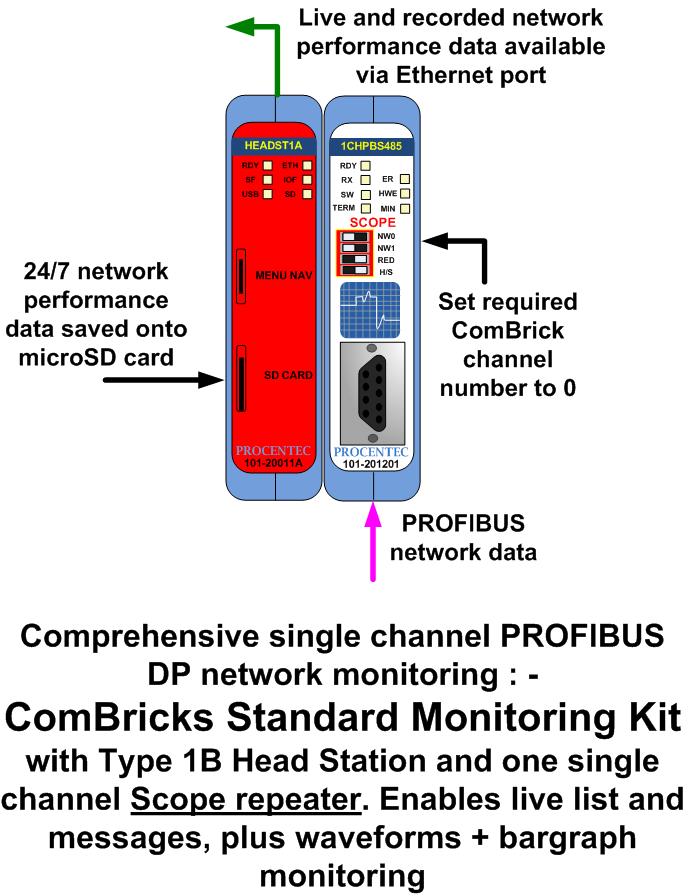

Enhanced Monitoring with Waveforms

With a ComBricks Scope repeater available, as in the above diagram, we are able to check the waveform shape and voltage levels on the connected segment, as well as checking for message failure statistics, if any. But it is important to remember that waveforms checks on any one segment will not apply to signals arriving from any other segments of that network if these are connected by repeaters or fibre optic modules, as these units will totally re-shape waveforms passing through them……but these devices will not change or influence actual message details, or any associated failure statistics.

Segment waveforms and connected device driver voltage level checks are still very useful if coming from devices within the connected segment, as they enable early indication of device or connection weaknesses, often before these can lead to any related message failures.

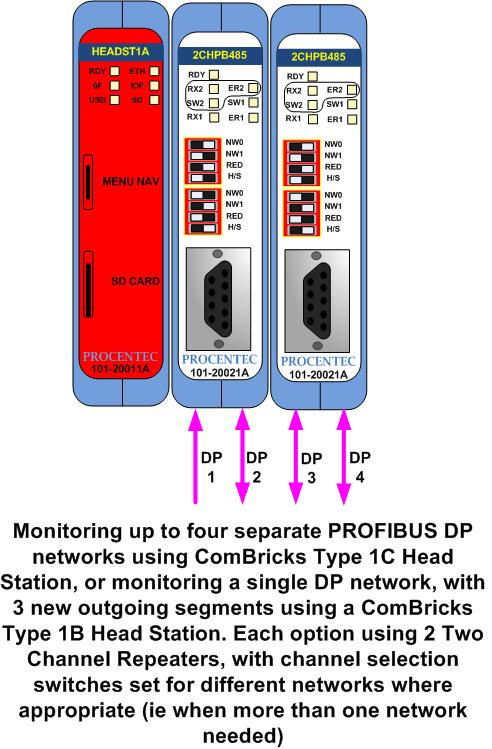

Basic 4 Network Monitoring

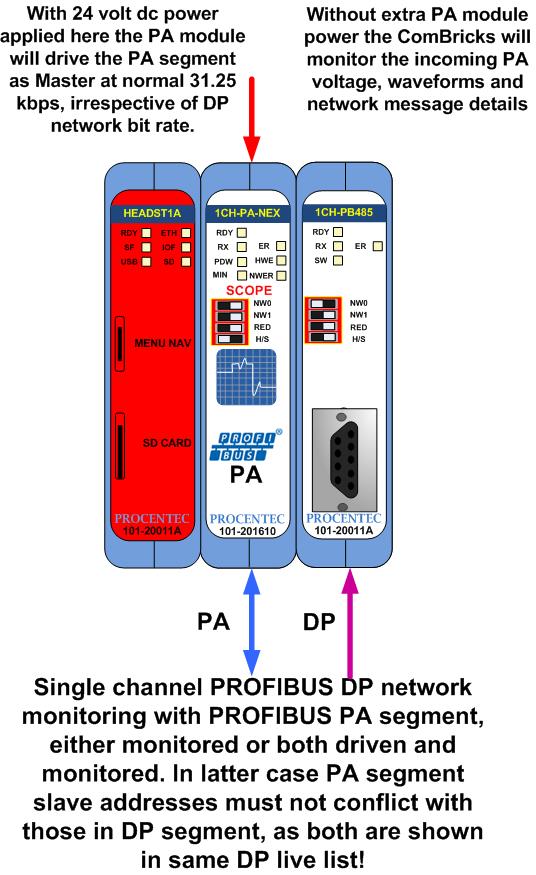

PROFIBUS PA Segment Master and/or Monitoring

The following diagram covers both the two module PA Monitoring Kit and the three module PA Coupler Monitoring Kit. The PA Monitoring Kit includes only the two left hand modules, with the third single channel repeater module only needed when the PA Module is required to drive the PA segment, taking source message details from a connected PROFIBUS DP network. When driving a new PA segment in this manner, up to 500 mA loading is available from the ComBricks module, at which new segment termination will also be automatically activated.