New ComBricks post – 2021

Procentec ComBricks provides a flexible range of PROFIBUS network performance monitoring and PROFIBUS message distribution modules, covering a diverse spread of different applications and structures. These run from simple single PROFIBUS network 24/7 performance monitoring sets, with local result logging and remote access features, to complex hub arrays potentially covering up to 4 different PROFIBUS networks, each with many additional copper, fibre and/or PROFIBUS PA segments and scope for redundant channel and/or fibre ring arrangements.

An important common feature is the powerful web server integrated into each ComBricks Head Station, which both allows easy configuration and set-up of all connected modules, but also facilitates remote access for immediate real-time inspection of current network status and access to stored performance history records for each of the associated networks!

If you are new to ComBricks then maybe review our Quick Start Your First ComBricks Project article here which might be helpful , as this explains how to install and set-up a basic ComBricks Eco Monitoring system. Then possibly review our ComBricks drawing set, which shows how this basic kit can be changed, with alternative modules, to cater for many different applications.

Additionally, checkout the remote access view of the live ComBricks demo equipment which is usually running in the Procentec premises. This starts showing the ComBricks Network 1 Live List, similar to that available from ProfiTrace. Selection of the left hand Channel List shows diagram of the various ComBricks modules currently running, together with outline information for all connected segments and the slaves connected to each. At time of writing, this setup includes a Type 1B Head Station, connected to an incoming segment from Master at network address 2, via a single channel ComBricks Scope repeater, linking slaves with addresses 12 (B5+R repeater with diagnostic mode selected), 52, 62, 72 and 123, with last device seen on the network by the Master, but not in data exchange. The B5+R repeater is set for diagnostic operation with slave address 12, and two operational segments, one connecting slaves 62 and 123, and the other connecting slave 52.

Further ComBricks modules, connected to the Head Station via internal backplane, provide fibre cable linking to a remote optical link module connecting to slaves with addresses 32 and 42, and a ComBricks PA Link module connecting to a single PROFIBUS PA slave with address 82. A single channel ComBricks Repeaters, shown in slots 1, is not used, either is the 4 channel relay module shown in slot 6 and the Scope repeater shown in slot 7. An RS485-IS Scope repeater is shown in slot 3, linking two RS485-IS slaves with addresses 22 and 92 (not in data exchange).

Particular attention is drawn to the recently added ComBricks web server Diagnostic slave info page, accesses by left hand link near top of list – as this reveals comprehensive status information provided from the B5+R slave.

Procentec ComBricks Eco Monitoring kit

Part No. 101-200QBR – this is the very basic, but powerful and useful, ComBricks single PROFIBUS network performance monitoring kit. It is typically mounted near to a network PLC/Master and is used to monitor and check for potential low level network performance failures.

More InfoThese will show as Repeat, Lost or Sync messages – incidents of which will be saved to front panel microSD memory card for remote access later, and/or can be used to trigger local alarm by setting of the internal Head Station relay.

Kit includes Head Station Type 1B and Single Channel Repeater

Procentec ComBricks Standard Monitoring kit

Part No. 101-200QBS – this more powerful kit also enables monitoring of a single PROFIBUS network performance, but here extends the capabilities of the Eco Monitoring kit, adding associated device waveform and bar-graph voltage level inspections – much as would be seen using a ProfiTrace analyser connected at the same point.

More InfoAs with ProfiTrace, these waveforms and voltage measurements will only be valid for the particular copper segment to which the kit is connected, and not those coming via any connected repeaters or OLM units.

Procentec ComBricks PROFIBUS PA Monitor kit

Part No. 101-200BP – this is a basic PROFIBUS PA segment monitoring kit, allowing waveform and voltage checking for a connected PA network, including DC noise, signal amplitude and jitter.

More Info

Kit includes Type 1B Head Station and Single Channel PA Coupler/Link Module

Procentec ComBricks PROFIBUS PA Coupler and Monitor kit

Part No. 101-200QBPR – this enhanced PROFIBUS PA coupler and monitoring kit, allows simple, transparent, connection and powering of a single PA segment, providing up to 500 mA to the connected devices.

Kit includes Type 1B Head Station, Single Channel DP Repeater and Single Channel PA Coupler/Link Module

More InfoThe PA Link module requires no set-up and operates is a very similar way to a normal ComBricks DP repeater. In isolation, with a ProfiTrace kit connected to the DP input repeater this equipment may be used to set-up PA slave unit adddresses, and check operation of individual PA units by running ProfiCaptain (ProfiTrace Master software) in Stop Mode.

Procentec ComBricks Fibre Optic kit

Part No. 101-200QAFR – this kit enables transparent, bi-direction, PROFIBUS message transfers between copper DP segment and multimode fibre optic cables. A single channel ComBricks Repeater and two channel Fibre Optic Module are powered from a Type 1A Head Station.

More InfoThis basic Head Station unit includes a reduced function web server which does not include the embedded ProfiTrace OE network performance monitoring features, which are included in the Type 1B and Type 1C Head Stations. The two fibre channels offfered may be configured for redundant operation, but not ring structure function.

Procentec ComBricks Advanced Monitoring kit

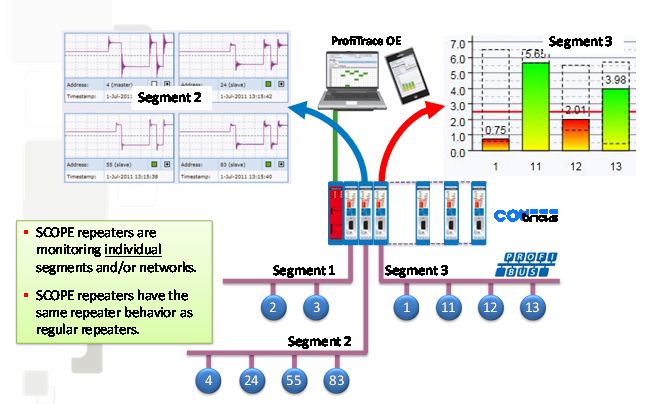

Part No. 101-200QC4S – This powerful kit, with a Type 1C Head Station and four Scope repeaters, enables monitoring of network performance for four different PROFIBUS networks, or of up to four different segments of one or more networks.

More InfoAs with the single channel Standard Monitoring Kit above, the Scope repeaters allow monitoring and reporting of both network messages and voltages/waveform details on each connected segment.

ComBricks Head Station Type 1C

Part No. 101-20011C – this is the most capable of all ComBricks Head Stations and allows drive and performance monitoring of up to 4 different PROFIBUS networks, or 4 separate segments of one or more different networks.

More InfoEach ComBricks Head Station provides power to connected ComBricks modules and hosts a ComBricks Web Server to provide control and connected network performance logging from each set and allows configuration, programming and network performance detail reporting from each associated kit via the top Ethernet port. Each ComBricks Head Station also includes a programmable relay to record any pre-selected network performance failure events, together with an associated top connector for linking to an external lamp or other alarm reporting system.

ComBricksHead Station Type 1B

Part No. 101-20011B – this is a slightly reduced capability version of the Type 1C ComBricks Head Station and here only allows drive and performance monitoring for a single PROFIBUS network.

More InfoAs for the Type 1C Head Station, the Type 1B Head Station provides power to connected ComBricks modules and hosts a ComBricks Web Server to provide control and connected network performance logging for each set and allows configuration, programming and network performance detail reporting from that kit.

ComBricks Head Station Type 1A

Part No. 101-20011A – this is a substantially reduced capability version of the Type 1B or 1C ComBricks Head Stations and here only allows drive for a single PROFIBUS network.

More InfoAs for the Type 1B or 1C Head Station, the Type 1A Head Station provides power to connected ComBricks modules and hosts a reduced capability ComBricks Web Server to provide control and programming, without performance monitoring, storage or reporting of details from the connectted network.

ComBricks 1 Channel Repeater

Part No. 101-201101 – this is the basic single channel ComBricks repeater which may be used for input or output of network message signals from or to a connected PROFIBUS segment.

More InfoIn the simplest ComBricks arrangement, one single channel repeater may be used with Type 1B Head Station to monitor and log message details for the connected segment, reporting this information over the Ethernet port from the internal web server. If a second single channel ComBricks Repeater is connected onto the ComBricks backplane alongside the first repeater, this may be used to drive a totally new full spec. outgoing PROFIBUS Segment. Note that these repeater modules include a 9-pin PROFIBUS signal input or monitoring connector on the front face. This may be used in place of the green underside PROFIBUS signal input/output connectors, or for signal monitoring using ProfiTrace.

ComBricks 2 Channel Repeater

Part No. 101-201102 – this is the enhance two channel ComBricks repeater which may be used for input or output of network message signals from or to a connected PROFIBUS segment.

More InfoIf one of these Two Channel Repeaters is used with a Type 1B Head Station, that system can not only monitor and log message details for the primary incoming connected segment, reporting this information over the Ethernet port from the internal web server, but also drive a completely new, full spec. outgoing segment from the second channel . Note that these repeater modules include a single 9-pin PROFIBUS signal input or monitoring connector on the front face. This may be used in place of the green underside Channel 1 PROFIBUS signal input/output connector, or for monitoring signal details on that network using ProfiTrace. There is no equivalent 9-pin input or signal monitoring connector for the top Channel 2 PROFIBUS segment. Note that two separate 4 slide DIL switch sets are provided on the front panel, with the top pair of switches in each set used to set the required channel number to which each of the two PROFIBUS channels is to be assigned within that ComBricks backplane – in range 0, 1, 2 or 3.

ComBricks Scope Repeater

Part No. 101-201210 – this is a very much enhanced version of the single channel ComBricks Repeater, here adding measurement and display of connected PROFIBUS message waveforms and driver voltages.

More InfoThese extra message details then available for display by the connected Head Station web server for remote inspection, using a browser program, in a similar style to that shown by a locally connected ProfiCore Adapter and ProfiTrace ScopeWare software. Once again, the top two front panel DIL slide switches must be set for allocation of the incoming PROFIBUS signals and assiated details to one of the 4 possible ComBricks backplane channels.

ComBricks Fibre Optic Module

Part No. 101-201510 – this is the original ComBricks fibre optic module, with two separate fibre output channels for point-to-point, bus, star and hub topologies. Aternative modules are offered for SM and MM fibre ring connection

ComBricks MM Fibre Ring Module

Part No. 101-201530 – this module allows connection of Multi-Mode fibre rings for enhanced reliability. Distances up to 5 km possible and ideal for heavy EMC environments

More InfoMay be used for connection to similar ComBrick modules, or networks including Procentec ProfiHub B2FO2+MM and/or B4FO2+MM repeaters

ComBricks SM Fibre Ring Module

Part No. 101-201531 – this module allows connection of Single-Mode fibre rings for enhanced reliability. Distances here up to 20 km possible and ideal for heavy EMC environments

More InfoMay be used for connection to similar ComBrick modules, or networks including Procentec ProfiHub B2FO2+SM and/or B4FO2+SM repeaters

ComBricks PA Link / Coupler Module

Part No. 101-201610 – The versatile, transparent PROFIBUS PA link/coupler enables seamless high speed integration of a PROFIBUS PA segment to a PROFIBUS DP segment connected into the Combricks, then operating either as a PA segment performance monitor, or as a PA segment Master.

More Info

For PA Master functions, 24 v DC must be applied via the top connector, this powering attached PA devices on the PA segment, fully emulating them as DP devices on the Combricks backplane and showing each PA device in the normal DP Live List. In addition to these operational roles, can also be used with ProfiTrace connected to the DP backplane and running ProfiCaptain software to set PA device slave addresses.

ComBricks IS Repeater

Part No. 101-201401C – this module provides intrinsically safe connection to remote RS485-IS segment devices, connected via front panel DB9 socket – using special RS485-IS plug.

ComBricks 4 ch Relay Module

Part No. 101-210210 – offers 4 isolated sets of relay contacts, with both normally open and normally closed contacts. Contacts rated for 230 VAC at up to 5 A. One set of contacts to front of module, with 2nd set below.

More InfoMay be controlled from the ComBricks web server in response to bus problems, or from the DP Slave Module

ComBricks DP Slave Module

PartNo 101-220210 – this multi-purpose unit not only operates as a normal ComBricks single channel repeater, but also PROFIBUS DP slave on a selected local ComBricks backplane to control associated Relay Module output settings and can also be used in similar manner to a regular DP/DP coupler for linking separate DP networks.

More InfoUnit slave address is set on rotary decade switches found on lower edge, or by software. Normal ComBricks channel selection slide switches also mounted on lower edge, with 2 for channel selection, 1 unused (‘nu’) and 1 for choice between Hardware or Server setting control.

ComBricks 6A Power Module

Part No. 101-230010 – this module is used to provide additional power to a multi-module ComBricks backplane, or may be used, with supply from a different 24 DC supply, as a redundant power source for that hub.